-

CCS Custom Solutions are automated or semi-automated marking, coding, or labeling systems tailor-made for your unique production. Custom built solutions are engineered to increase productivity and save you money. Whether you need label applicators, continuous ink jets, laser coders, or print and apply systems, we utilize top-of-the-line technology from reputable companies to make our customers’ automation dreams come true!

-

With over half a century of industry experience, countless custom solutions across the nation, and a shared passion for excellence and automation, the Chicago Coding team will accelerate your production and be there to provide lasting support!

-

Custom solutions come in a variety of configurations that are unique to the customer’s application. We start with the desired system type, and build it around your existing production line. There is not a one-size-fits-all system for every production need, but we love solving problems! So get in touch today to learn more about our custom solutions and how you can benefit.

No matter what industry you are in, we will help bring automation into your production processes. Check out examples of some of our Custom Solutions below, and make sure to watch the video demos! Get in touch with any automation ideas.

Variable Data

Print and Apply

This solution takes most of the work out of the operator's hands by automating label design changeover and application automatically. The vision system scans each container which informs the print engine to load and print the correct label, and applies it to every box! Watch a demo of this system below.

CoPilot Max UV Curing System

With three Copilot Max printheads you will get a massive area of print, able to print barcodes, instructions and logos in only one pass. This solution utilizes a Walco feeder / conveyor to move products quickly, and there are no worries over smeared print due to the immediate curing time with the UV light!

Print & Apply with Walco Conveyor

This system utilizes a Walco feeder and conveyor to move packages steadily and quickly down the conveyor belt. Once they pass the photocell, the tamp pad extends from the print and apply system, applying a freshly printed label onto each and every passing box! Walco systems are versatile and simple to operate.

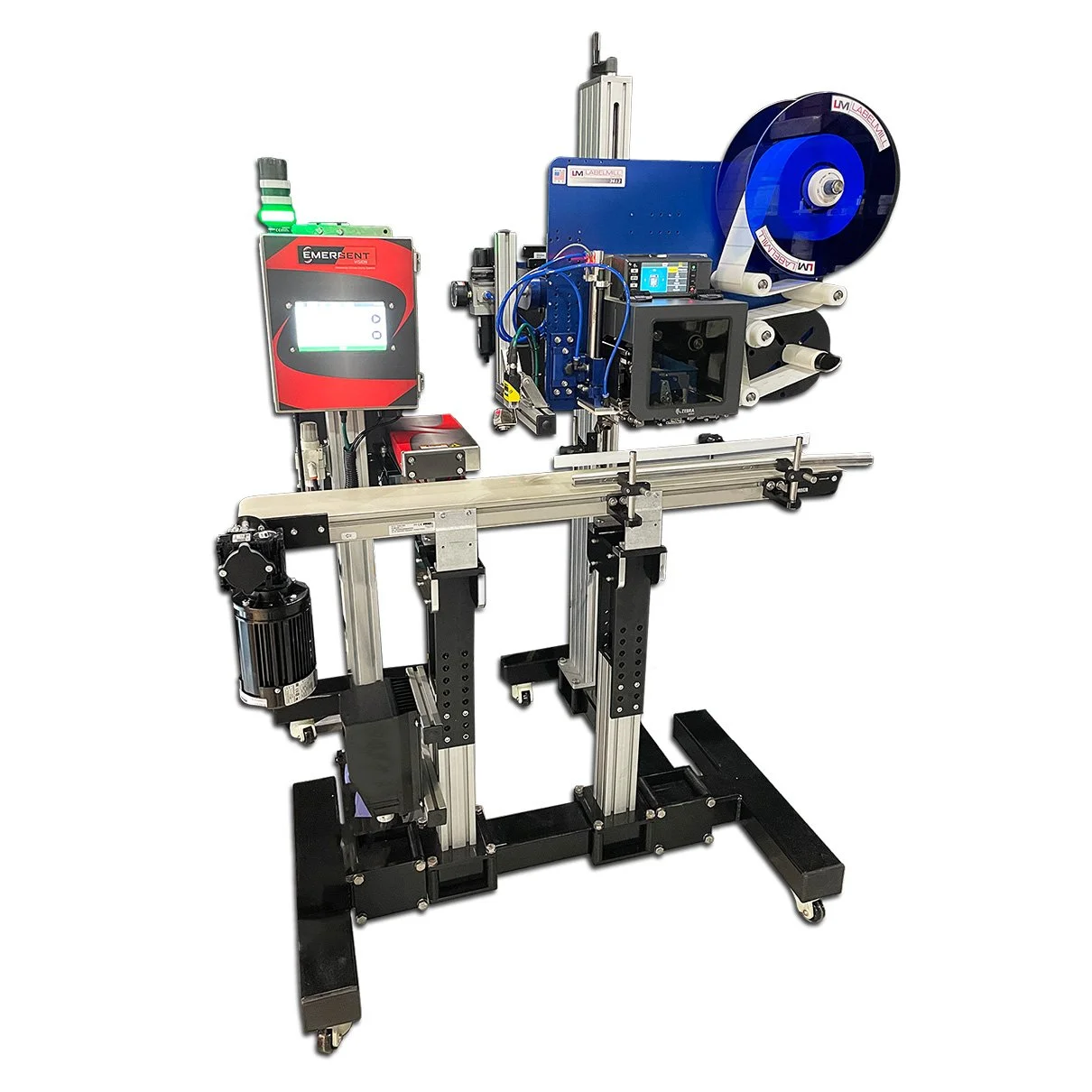

Smart Tamp Print & Apply w/ ZE511

The Smart Tamp application head is perfect for applying labels on to containers of varying heights, and the guide rails can be adjusted to accommodate wider cartons. The Zebra ZE511 print engine, in tandem with Teklynx’s Codesoft, is a powerful duo that works efficiently, quickly, and is ready to take on all of your labeling needs!

"Trap & Wrap” Labeling System

This custom solutions works as the title implies: trap the container and wrap the label around it! As the cylindrical container moves along the conveyor it triggers the wrap module to hold it, the printer to dispense a label, and the wrapping motor to spin the container in place. Leaving you with an accurately placed label in no time.

Smart Tamp Print & Apply Labeler

With its extended application arm and smart tamp module, this system can apply labels on pallets of different sizes, and at varying distances, all without damaging the arm. This smart tamp technology can also be flipped vertically and incorporated with print and apply conveyor systems. Perfect for labeling varying sized containers so that the labels always hit their mark!

Cylindrical Labeler TableTop System

TableTop Systems are widely popular thanks to their small footprint, ease of operation, and wide range of containers it can label! Quick and easy label application all at the push of a button. The applicator arm and rollers can be adjusted to accommodate various jars, tubes, syringes and more.

Print & Apply with Reject Station

This print and apply system utilizes Cognex machine vision and CCS’ Emergent reject station kit to verify each passing barcode is readable, contains correct information, and hasn’t been printed before. If a package/barcode fails this step, the reject arm is activated and pushes the package off the main line. Watch this system on our Youtube channel.

Wipe-on Label Applicator

A system made for small packages that need a descriptive label applied on top. As each package passes the photoeye a label is dispensed onto the container. The conveyor continues moving it down the line as the applicator brush secures the fit on top.

Dual Print & Apply

This system utilizes two LabelMill applicators and two Zebra ZE511 print engines to synchronously apply labels on either side of your carton. Adjustable guide rails and smart tamp heads allow for cartons of various sizes to ride the conveyor and still have labels apply quickly and accurately.

Print & Apply w/ Top Hold Down

This system has an active print and apply arm that meets the carton as it moves down the conveyor. The top hold down addition holds the cartons steady, and drives them through the tamp arm, allowing for a flush and efficient label application.

Label Applicator, Check Weigh & Reject Station

Label application and check weigh conveyor system utilizes pressure sensitive conveyor belts, a digital scale and a reject station to remove any incorrectly weighed products. Correctly weighed cartons continue down the line while rejected cartons are transferred off the main line for corrections.

Print & Apply Conveyor System

Utilizing a conveyor belt, adjustable guide rails, and a Zebra print engine, this solution prints the labels and applies them on top of the passing cartons. Systems like these have adjustable settings and fine-tuning capabilities in order to increase your overall efficiency and to seamlessly implement it into your existing production.

Top & bottom high speed labeling

This customized all-in-one system includes two conveyor belts, one TTO printer, and two label applicators. It has the ability to apply a label on both the top and bottom of the product as it moves across the belts, all while adding variable data to one side. This custom solution increases efficiency and productivity for the client by letting their production continue at the maximum output, all while maintaining traceability.

Table Top Syringe Labeler

Perfect for the pharma industry, our semi-automatic table top labeling system effortlessly applies labels around syringes and other cylindrical objects. The compact size of this applicator allows it to fit into tight spaces; and the easy to operate configuration means you’ll be up and running as soon as we deliver your innovative, custom solution!

Passive Print & Apply

Our print and apply systems are custom built to your production line’s specifications and are engineered to run at the most efficient pace for your product / packaging. The passive P&A systems let the cartons hit the arm, causing the label to stick to it, then flattening the rest of the label as the carton moves down the conveyor.